What are Industrial Blades

Industrial blades are precision-engineered tools designed to cut, slice, shave, trim, or shear through a variety of materials in industrial settings. These specialized blades are integral to the manufacturing processes of numerous industries, including but not limited to printing shops, construction sites, food processing plants, textile factories, and recycling facilities. Industrial blades can be crafted from a range of materials such as stainless steel and alloys, which are chosen for their durability and resistance to wear and corrosion.

The design and operation of industrial blades are governed by the principles of material science and engineering. They must maintain sharpness over extended periods and withstand the stresses of cutting tough materials. The effectiveness of an industrial blade is determined by its edge quality, the hardness of the material it is made from, and its ability to resist bending or breaking during use. Manufacturers often offer customization options such as OEM (Original Equipment Manufacturer) services to cater to specific cutting requirements or unique applications.

For businesses using these tools, industrial blades represent more than just simple cutting implements; they are a vital component in maintaining efficiency and productivity. Whether it's for slicing paper in a printing shop or cutting through metal in a manufacturing plant, these blades need to perform reliably under challenging conditions. In essence, industrial blades are not just tools but partners in production that help businesses keep their operations running smoothly.

Types of Industrial Blades

Industrial blades come in various shapes and sizes, each tailored for a specific task or industry. The diversity of blade types reflects the vast array of materials they are designed to cut and the different machines they are used with.

Utility Blades: Often found in retractable or fixed-handle knives, utility blades are general-purpose cutting tools used across multiple industries for tasks requiring precision and versatility. They can slice through packaging materials, roofing materials, flooring items like carpet, and more.

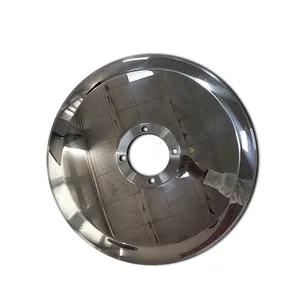

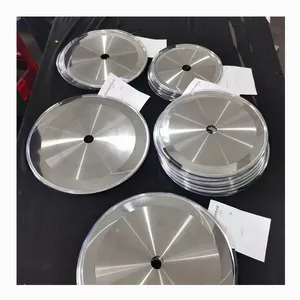

Circular Blades: These blades take the form of large discs with sharp edges and are used in slitting machines. They effortlessly cut through paper, rubber, leather, textiles, and other materials into specified widths or shapes.

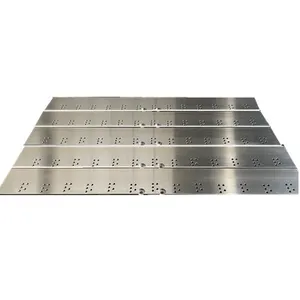

Straight Blades: Also known as shear blades or guillotine blades, these straight-edged knives are employed in applications where a straight cut is essential. They're often used in paper cutting machines within the printing industry or for shearing metal sheets in manufacturing plants.

Serrated Blades: With their saw-toothed edge, serrated blades excel at cutting materials that require a sawing motion. They're commonly used for packaging films or other tough-to-cut materials where a smooth blade might slip or fail to penetrate effectively.

Specialized Blades: These include uniquely shaped or specifically designed blades for particular tasks like cutting tobacco leaves or slicing food products. They may have distinctive features such as perforation or be made from special materials like zirconia ceramic.

How to Choose Industrial Blades

Selecting the right industrial blade is crucial for ensuring the efficiency and quality of your business's operations. When choosing an industrial blade, consider the material you will be cutting; different materials require different blade properties. Stainless steel blades might be preferred for their longevity whereas alloy blades could be selected for specialized tasks requiring sharper edges.

The type of machinery you have is another important consideration. Some machines require specific blade designs such as circular knives for slitting equipment or serrated blades for packaging machines. Moreover, the machinery test report can provide valuable insights into the blade's performance during standard tests.

Businesses should also consider whether they need customized support such as ODM (Original Design Manufacturer) services if they have unique requirements that off-the-shelf products cannot meet. The key selling points like long service life and ease of operation can guide decision-making towards blades that promise minimal downtime and user-friendly experiences.

Lastly, it is vital to consider the local service location because access to timely servicing and support can significantly impact productivity. A blade supplier who offers services in your country can be a better choice due to potentially quicker response times and easier access to replacement parts if needed.

Best Industrial Blades on Alibaba.com

Alibaba.com stands out as a global marketplace that brings together an extensive selection of industrial blades suitable for various applications across multiple industries. With over two decades of experience connecting buyers with reputable suppliers worldwide, Alibaba.com has established itself as an invaluable resource for businesses seeking high-standard industrial tools without geographical constraints.

The platform offers a spectrum of industrial blade options from suppliers who provide customizable solutions tailored to specific industry needs—whether you're looking for robust circular blades for heavy-duty cutting tasks or precise utility blades for intricate workmanship. The diversity available on Alibaba.com ensures that every business can find the exact type of blade required for their operations while benefiting from competitive pricing that comes with wholesale purchasing.

Furthermore, Alibaba.com's Trade Assurance service enhances buyer confidence by securing payments until delivery is confirmed satisfactory. Coupled with user-friendly features that facilitate easy navigation and communication in local languages on both desktop and mobile devices, Alibaba.com presents an efficient way for businesses around the world to source reliable industrial blades that meet both their quality expectations and operational demands.

Common FAQs for Industrial Blades

What are the core components to consider when selecting an industrial blade?

When selecting an industrial blade, core components such as the material (e.g., stainless steel or alloy), blade design (e.g., serrated, straight, circular), and compatibility with existing machinery (e.g., engine, motor, PLC) should be considered to ensure optimal performance and longevity.

How does blade material affect the performance of an industrial blade?

The material of an industrial blade affects its durability, sharpness retention, and suitability for cutting different materials. Stainless steel is known for corrosion resistance and overall longevity, while alloys may offer superior sharpness and cutting efficiency for specialized tasks.

Can industrial blades be customized for specific applications?

Yes, many suppliers offer customized support such as ODM or OEM services, allowing businesses to tailor industrial blades to their specific requirements regarding shape, size, material, and cutting properties.

What industries commonly use industrial blades?

Industrial blades are used in a variety of sectors including manufacturing plants, machinery repair shops, printing shops, construction sites, food processing industries, garment shops, and more where precise cutting is crucial.

How do I determine the right type of industrial blade for my business?

Determining the right type of industrial blade involves understanding the material to be cut, the required precision and edge quality, the machinery used in your operations, and any specific industry standards or requirements.

What should I consider about local service locations when purchasing industrial blades?

Considering local service locations is important for ensuring you have access to support services such as blade maintenance or sharpening. It also helps in reducing downtime due to quicker response times and part replacements if needed.

How can I verify the quality of an industrial blade before purchasing?

Quality can often be verified through machinery test reports provided by suppliers which detail the performance of the blade under standard testing conditions. Additionally, looking at the supplier's certifications and past customer reviews can provide insights into quality expectations.

Are there industrial blades designed for both heavy-duty tasks and precision work?

Yes, there are heavy-duty blades designed for robust applications such as cutting metals or hard materials and precision blades engineered for intricate cuts requiring exactness and fine detail.

How does the processing type of an industrial blade (hot press vs. cold pressed) influence its use?

The processing type can influence the hardness and durability of the blade. Hot-pressed blades typically have a finer grain structure resulting in improved toughness, while cold-pressed blades may have higher hardness levels but could be more brittle.

What are key selling points I should look for in industrial blades?

Key selling points to consider include long service life and ease of operation which translate to reduced maintenance costs and user-friendly experiences during cutting tasks.

What materials are commonly cut with industrial blades?

Industrial blades are used to cut a wide range of materials including paper, rubber, food products, textiles, metals, plastics, wood, and more depending on the specific blade type and industry application.

How often should I replace or maintain my industrial blades?

The frequency of replacement or maintenance depends on usage intensity, material being cut, and blade quality. Regular inspections can determine wear patterns and help schedule timely replacements or sharpening to maintain efficiency.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4