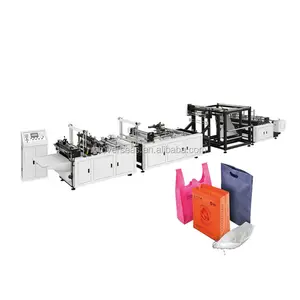

A non-woven bag-making machine is a machine that is used for the manufacturing of bags. It basically suits all kinds of non-woven fabrics such as spun cotton, thermoplastic films, chemical plastic scraps, polyester, nylon, sponge, etc.

Different types of non-woven bag-making machines and their features

Spunbond non-woven machine is equipped with microcomputer control, photoelectric tracking, automatic deviation correction, and an ultrasonic welding system. The machine's operations should be intuitive and easy to operate. Due to the convenience of switching functions, bags can be made in a variety of styles using the non-woven machine operator. Non-woven machine forming fabric is a piece of ideal equipment for producing non-woven bags, D-cut bags, shoe bags, and handle bags. Manual bag non-woven machines can be operated with different specifications and can make various shapes of three-dimensional bags, non-woven bags, and vest bags according to user's preferences. In order to create sturdy and beautiful bag products. The semi-automatic non-woven bag machine is equipped with industrial control devices such as an automatic punching system. It is equipped with an overlock feature that will make the edges of the bags being made not become too stringy. With a 2000 rpm machine speed, the overlapping process can be carried out easily and effectively with neat stitches. Apart from the overlock system, the flower sleeve bag-making machine can also be used to make edge stitches in the bags. The side-sealing bag-making machine has a strong body frame structure because it is made of metal and stainless-steel materials. The disposable cap non-woven machine is equipped with 23 stitch patterns in this machine, so it can make buttonholes quickly and easily. Users can check their thread supply more easily because the thread cover is made transparent. The automatic garbage bag-making machine is suitable for all kinds of non-woven fabrics, chemical fibers, plastics, and composite materials. It is widely used in advertising bags, gift bags, shopping bags, sturdy non-woven bags, and laminated non-woven bags.

Why is it necessary to clean a non-woven bag-making machine regularly?

The photoelectric tracking lamp holder needs to be cleaned regularly to check whether there are errors in the cursor tracking. It is a must to clean the dust in the electrical control box regularly to prevent poor contact from delaying production. The machine must be inspected, tightened, and oiled within one week of use for a smoother device transmission.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4