Introduction to Ball Screw 1202

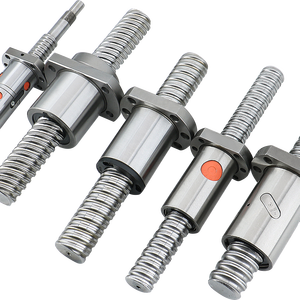

Ball screws are pivotal components in modern machinery, providing precise motion control essential for automation and CNC applications. The ball screw 1202 is a specific category within this broad field, designed to convert rotational motion into linear motion with minimal friction. This type of ball screw is particularly known for its compact size and reliability in various applications.

Types and Applications

The versatility of the ball screw 1202 is evident in its various types, each tailored for specific applications. Precision lead ball screws offer high accuracy for CNC machines and robotic arms, while standard lead rolled screws provide a cost-effective solution for less demanding operations. Rotary nut screws are ideal for applications with limited space, as the nut rotates instead of the screw. These components are integral in industries ranging from medical equipment manufacturing to aviation and metalworking.

Features and Materials

A ball screw 1202 is characterized by its features that cater to demanding industrial environments. The materials used in manufacturing, such as alloy steel or stainless steel, are selected for their durability and resistance to wear. The design of these screws often includes a ball return system that ensures smooth operation and a long service life. The thread diameter and pitch can be tailored to meet the load and speed requirements of various applications.

Advantages of Ball Screw 1202

The ball screw 1202 offers several advantages over other mechanical actuators. Its efficiency in converting rotary to linear motion minimizes energy loss, making it suitable for high-load applications. The precision of movement it provides is crucial for applications requiring meticulous motion control. Additionally, the reduced friction during operation leads to less heat generation and extends the lifespan of the machinery it is a part of.

Selection Considerations

When selecting a ball screw 1202, it is essential to consider the axial load requirements and the ease of assembly based on the equipment's complexity. The design should ensure compatibility with the existing machinery, such as CNC machines, to facilitate seamless integration. It is also important to consider the type of motion control required, whether it is for high-speed automation or precision engineering tasks.

Conclusion

In conclusion, the ball screw 1202 is a critical component in various industrial applications, known for its precision, efficiency, and adaptability. With a range of types and materials available, these screws can be tailored to meet the specific needs of any operation. While selecting the appropriate ball screw, it is crucial to analyze the application's requirements to ensure optimal performance and longevity.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4