Related Searches:

Top categories

About bluetooth speaker pcb design

Exploring Bluetooth Speaker PCB Design

The realm of audio technology has seen a significant evolution with the advent of Bluetooth speaker PCB design. This intricate field encompasses the creation of printed circuit boards (PCBs) specifically tailored for Bluetooth speakers, which are pivotal in defining the functionality and performance of these audio devices. The design process involves a meticulous consideration of electronic components, circuitry, and connectivity to ensure seamless audio transmission and quality.

Types and Applications

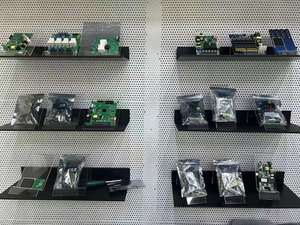

Bluetooth speaker PCBs come in various forms, catering to a diverse range of applications. From compact, portable models to more sophisticated systems for professional use, the PCBs are designed to meet the specific needs of each speaker type. They are integral in consumer electronics, automotive audio systems, and public address systems, providing the necessary circuit framework for wireless audio solutions.

Design Features and Materials

The design of a Bluetooth PCB module is a complex task that requires precision. It typically involves multi-layered PCBs that accommodate Bluetooth modules, amplifiers, and other essential components. The choice of materials for these PCBs is crucial, with options like FR4 or CEM3 being common due to their durability and effective electrical insulation properties. Advanced designs may also incorporate flexible PCBs for speakers with unique form factors.

Technical Advantages

Bluetooth speaker PCBs are engineered to optimize signal integrity and minimize interference, which is vital for maintaining sound quality in wireless connections. The integration of advanced technologies in PCB assembly for Bluetooth speakers ensures low power consumption, extended battery life, and compatibility with various Bluetooth versions. These PCBs are also designed for ease of integration with different speaker components and housings.

Customization and Manufacturing

Manufacturers offer a range of customization options for Bluetooth audio PCB designs to accommodate the needs of different speaker models. This includes variations in PCB size, component placement, and connectivity options. The manufacturing process adheres to stringent standards to ensure the reliability and longevity of the PCBs, without making any guarantees on behalf of the platform.

Environmental Considerations

In the production of Bluetooth speaker circuit boards, environmental considerations are taken into account. The use of lead-free HASL (Hot Air Solder Leveling) finishes is a common practice to comply with environmental regulations and to ensure the safety of the product for both the users and the environment.