Popular in your industry

Related Searches:

Top categories

About cement tile mould

The Function of Tile Moulds in Cement Applications

Specialized in the realm of manufacturing, tile moulds for cement applications are instrumental in crafting an array of cementitious products, including floor and wall tiles, as well as pavers. These moulds are indispensable for enterprises mass-producing such items, as they guarantee both consistency and efficiency throughout the production cycle. Their clientele is diverse, encompassing construction firms, decorative item producers, and purveyors of garden embellishments.

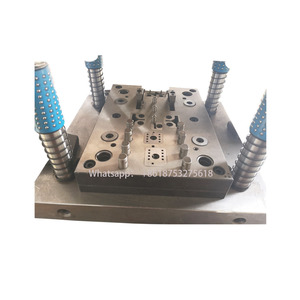

At the core of tile moulds for cement applications lies the objective to deliver a precise and uniform shape that can be reproduced with ease. Crafted from robust materials like silicone rubber or steel, these moulds are chosen for their longevity and their capacity to preserve the design's fidelity. The selection of mould material is contingent upon the product's specific demands and the magnitude of production.

In operation, tile moulds create a void into which cement is poured or pressed. Following the cement's setting and curing, it is extracted from the mould, yielding the intended product. This procedure can be conducted manually or with mechanical assistance, depending on the production's scale and the intricacy of the mould's design. Precision engineering plays a pivotal role in the creation of these moulds, ensuring they adhere to stringent dimensional tolerances and can endure the rigors of the cement casting process.

Varieties of Tile Moulds for Cement Applications

The assortment of tile moulds mirrors the varied demands of the construction sector. Each variant is tailored with particular features to suit distinct uses:

-

Hydraulic Press Moulds: Employed in the fabrication of high-density tiles like porcelain and vitrified types, hydraulic press moulds exert pressure on the tile blend to form a compact and robust tile. They are favored in industrial contexts for their prowess in churning out voluminous tile batches of unwavering quality.

-

Extrusion Moulds: This technique involves propelling the tile material through a die to generate a consistent profile. Extruded tiles are celebrated for their shape uniformity and are typically chosen for the production of borders or skirting tiles that demand straight edges.

-

Die Casting Moulds: Optimal for tiles with complex patterns or textures unattainable via extrusion, die casting moulds are the go-to for artistic ventures or when specialized industrial equipment is lacking.

-

Compression Moulds: Designed for high-density tiles, compression moulds utilize a mixture that is compacted under high pressure within a moulding apparatus, resulting in an exceptionally durable tile. These moulds are predominantly used for flooring where resilience is crucial.

Each mould type is chosen based on project-specific criteria, such as the required tile density or design complexity.

Selecting the Appropriate Tile Mould for Cement Applications

Choosing the correct tile mould for your enterprise involves a thorough understanding of your production needs and the characteristics of the tiles you intend to manufacture. Consider the following:

-

Tile Type and Size: Assess the variety of tile you are crafting and its measurements. Different categories, such as floor or wall tiles, may necessitate distinct mould designs that align with their unique contours.

-

Material Compatibility: Your mould's material should be congruent with the substance used for tile production. For example, when dealing with cement-based items, a silicone rubber mould capable of withstanding abrasive materials is required.

-

Production Volume: The quantity of tiles you plan to produce will influence your mould choice. For large-scale production, opt for more resilient materials like metal or premium silicone rubber that can endure repeated usage.

-

Precision Requirements: The precision level necessary for your end product will guide your mould selection. Certain applications may call for highly detailed, custom designs that necessitate intricate moulds.

-

Runner Type: Your machinery and process may dictate the choice between hot runner or cold runner systems, which can affect the efficiency and quality of your production line.

By considering these elements and exploring Alibaba.com's vast array of suppliers and products, businesses can make well-informed decisions that align with their operational objectives and quality standards.

Exploring Tile Moulds for Cement Applications on Alibaba.com

Alibaba.com distinguishes itself as a leading online marketplace, offering a comprehensive selection of tile moulds for various cement applications. Whether the goal is to produce standard bricks or specialized tiles for decorative use, Alibaba's global network connects buyers with suppliers equipped to meet specific requirements. The platform provides everything from high-precision moulds for intricate designs to eco-friendly options for sustainability-focused projects, catering to every construction need.

The platform's commitment to smooth international trade is underscored by features such as mobile purchasing and support for multiple languages. This dedication ensures that, irrespective of your business's location or requirements, sourcing tile moulds through Alibaba.com is a streamlined experience tailored to your professional demands.

Furthermore, Alibaba.com's Trade Assurance service offers peace of mind by protecting your payments until your order is successfully received. This customer protection bolsters confidence in Alibaba.com as a source for wholesale tile moulds, aiding businesses globally in realizing their unique projects.

Frequently Asked Questions About Tile Moulds for Cement Applications

What are the primary advantages of employing tile moulds in manufacturing?

Tile moulds significantly diminish production expenses by enabling precise and consistent fabrication of ceramic tiles. They also enhance the manufacturing process's efficiency, ensuring tile quality remains uniform.

How should I ascertain the most suitable tile mould for my enterprise?

Identify the tile mould that aligns with your business's specific needs, considering factors such as the tile variety, the material in use, the desired attributes of the final product (e.g., eco-friendliness or high precision), and compatibility with your runner system.

Is it feasible to tailor tile moulds to my business's requirements?

Indeed, numerous suppliers on Alibaba.com provide customization services for tile moulds to accommodate particular design specifications or tile dimensions. Direct communication with suppliers is recommended to explore customization possibilities.

Which materials are commonly utilized for tile mould production?

Tile moulds are typically constructed from materials like silicone rubber, stainless steel, or aluminum alloy, chosen for their durability and their capacity to replicate detailed designs.

Are there eco-friendly tile mould options for businesses prioritizing sustainability?

Eco-friendly tile moulds are indeed available, often made from sustainable materials such as silicone or natural rubber, catering to businesses that place a premium on environmentally responsible production practices.

What significance do runner systems hold in tile moulding?

Runner systems are essential as they ensure the smooth flow of molten material into the mould cavity, filling out all areas of the mould evenly and reducing material wastage.

How can I guarantee the quality of the tile moulds I procure?

To ensure quality, opt for moulds from verified suppliers who offer comprehensive product details and boast positive ratings and reviews. Additionally, Alibaba.com's Trade Assurance service provides an added security layer for your transactions.

Do ceramic tile moulds have specific maintenance needs?

Ceramic tile moulds generally necessitate routine cleaning and dry storage to avert moisture accumulation that could compromise mould quality. Some may also require periodic lubrication to facilitate the smooth release of finished tiles.

Is it permissible to use the same tile mould for different clays or materials?

This is contingent on the tile mould's design and the material it is made from. Some moulds are versatile enough to accommodate various clays, while others are tailored for specific materials to ensure proper shaping and longevity.

How do I select the correct tile mould size for my project?

Take into account the dimensions of the final product you aim to create. The mould should conform to your product's size specifications, allowing for any necessary spacing or edge treatments.

Can I find tile moulds tailored for specific uses, such as roofing or flooring?

Certainly, tile moulds are available for a range of applications, including roofing and flooring. It is crucial to select a mould that meets the particular demands of your project.