The coconut shell charcoal making furnace is a specialized piece of equipment designed to convert coconut shells into high-quality charcoal through a process of carbonization. This machinery is crucial for businesses aiming to capitalize on the demand for eco-friendly charcoal alternatives.

Types and Characteristics of Coconut Shell Charcoal Making Furnaces

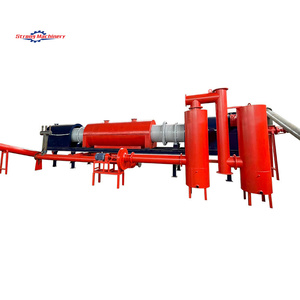

Within the category of coconut shell charcoal making furnaces, there are several types, each with unique characteristics. Batch furnaces are suitable for small-scale operations, allowing for flexibility in production schedules. Continuous furnaces, on the other hand, are designed for larger operations, with a focus on mass production and efficiency. Some furnaces incorporate advanced features like automated temperature control and real-time monitoring systems, which enhance the precision of the carbonization process. The choice between a drum furnace, a rotary kiln, or a vertical kiln will depend on the desired throughput, the quality of charcoal needed, and the specific production goals of the business.

Structure and Operation of the Charcoal Furnace

The coconut shell charcoal making furnace is meticulously engineered, with each component playing a pivotal role in its operation. The carbonization chamber, where the raw material is converted into charcoal, is the heart of the furnace. It is designed to maintain a low-oxygen environment to prevent combustion and ensure proper carbonization. The feeding mechanism, which may be a conveyor belt or a hopper system, is tailored to deliver coconut shells into the chamber at a consistent rate. The ignition system is built with safety and efficiency in mind, often using electric heating elements to initiate the carbonization process. The exhaust system not only manages fumes but also recycles heat to improve overall energy efficiency.

Materials and Properties in Charcoal Furnace Construction

The construction materials of a coconut shell charcoal making furnace are selected for their ability to withstand high temperatures and corrosive gases. The use of stainless steel and alloys in the outer structure provides resistance to heat and ensures the longevity of the furnace. The interior is lined with refractory bricks or ceramics, which offer excellent thermal insulation, maintaining high temperatures while preventing heat loss. These materials are also resistant to the acids and alkalis that may form during the carbonization process, ensuring the furnace's durability and consistent performance.

Business Usages and Applications Across Industries

The coconut shell charcoal making furnace is a versatile tool used across various industries. In the manufacturing sector, it is crucial for producing activated carbon, which is used in water treatment plants and air purifiers. In agriculture, the charcoal serves as a soil enhancer, improving soil health and supporting sustainable farming practices. The energy sector values the charcoal for its renewable energy potential, using it as a cleaner alternative to traditional fossil fuels. These usages underscore the furnace's role in not only generating economic value but also in promoting environmental sustainability.

Functions and Tasks Performed by the Charcoal Making Furnace

The primary function of a coconut shell charcoal making furnace is to carbonize coconut shells into charcoal. However, it is also capable of processing other types of biomass, such as wood chips, sawdust, and rice husks. The furnace can be adjusted to produce charcoal with specific properties, such as varying levels of porosity and density, making it suitable for a wide range of end-uses, from barbecue briquettes to high-grade fuel for industrial furnaces.

Features and Unique Selling Points

Key features of the coconut shell charcoal making furnace include its energy-efficient design, which reduces operational costs, and its automated control systems, which ensure a consistent quality of the end product. Some models offer real-time data logging and remote monitoring capabilities, allowing operators to optimize the carbonization process and quickly respond to any issues. These technological advancements provide a competitive edge in the market, distinguishing these furnaces from less sophisticated alternatives.

Benefits and Positive Outcomes for Users

Adopting a coconut shell charcoal making furnace brings numerous benefits to users. It enables the conversion of agricultural waste into a commodity with economic value, thereby contributing to waste reduction and environmental conservation. The production process itself is cleaner compared to traditional charcoal-making methods, resulting in lower emissions and a smaller carbon footprint. For businesses, this translates into compliance with environmental regulations and an enhanced brand image as a green enterprise.

How to Use the Charcoal Making Furnace Effectively

To use a coconut shell charcoal making furnace effectively, operators must ensure that the raw material is properly prepared, with coconut shells being dried to the appropriate moisture content before carbonization. The furnace should be preheated to the optimal temperature to ensure efficient carbonization. Operators should also be trained to monitor the system's parameters and make adjustments as needed to maintain the quality of the charcoal produced.

How to Choose the Right Charcoal Making Furnace

Selecting the appropriate coconut shell charcoal making furnace involves evaluating the scale of operation, the desired quality of charcoal, and the specific requirements of the end product. It is also important to consider the availability of after-sales services, such as technical support and access to spare parts, to ensure uninterrupted operation. Buyers should seek furnaces that offer a balance between advanced features and ease of use, ensuring that the equipment can be operated effectively by their team.

How to Clean and Maintain the Charcoal Furnace

Regular cleaning and maintenance of a coconut shell charcoal making furnace are essential for optimal performance. This includes the removal of ash and residue from the carbonization chamber, inspection and cleaning of the exhaust system to prevent blockages, and checking for wear and tear on mechanical parts. Adhering to a maintenance schedule can prevent unexpected downtime and extend the service life of the furnace.

How to Install the Charcoal Making Furnace

The installation of a coconut shell charcoal making furnace should be conducted in accordance with the manufacturer's instructions. It requires a solid foundation to support the weight of the furnace, proper ventilation for safe operation, and connections to the required utilities. Professional installation ensures that the furnace operates safely and at its highest efficiency.

Target Audience and Meeting Their Needs

The target audience for coconut shell charcoal making furnaces includes businesses in regions with abundant coconut production, such as Indonesia and Vietnam. The furnace meets their need for efficient waste utilization, providing a sustainable method to produce a high-demand product while contributing to local economies.

What After-sales Services Can You Expect?

After purchasing a coconut shell charcoal making furnace, buyers can expect comprehensive after-sales services, including field maintenance and repair services, as well as video technical support. Engineers may also be available to service machinery overseas, ensuring that any issues can be promptly and effectively resolved.

By integrating these detailed aspects into the product introduction, potential buyers on Alibaba.com can gain a comprehensive understanding of the coconut shell charcoal making furnace, its applications, and the value it can bring to their business operations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4