Popular in your industry

Related Searches:

Top categories

About coil winding rewinding machines

Introduction to Coil Winding Rewinding Machines

Coil winding rewinding machines are essential tools in the production and maintenance of electrical coils. These machines are pivotal in creating precise and efficient coils that are integral to the functionality of transformers, induction machines, electric motors, and various electronic devices. The versatility of these machines makes them indispensable in industrial manufacturing and repair services.

Types and Applications

The range of coil winding machines varies from manual to fully automated CNC systems. Manual winders are suitable for smaller operations such as educational settings or workshops, where precision and customization are key. On the other hand, CNC coil winders are designed for high-volume production, featuring automation panels that allow for continuous and consistent output. Between these two extremes lie semi-automated machines that offer a balance of mobility and functionality, ideal for repair shops and small-scale manufacturing.

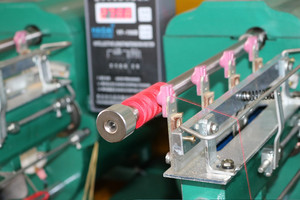

Features and Specifications

Automatic coil winding machines boast features that cater to a variety of industrial needs. These include adjustable loading weights, coil dimension variability, and different production rates to match the scale of operation. Certain models are also capable of handling toroid coil production, showcasing the adaptability of these machines to various production requirements.

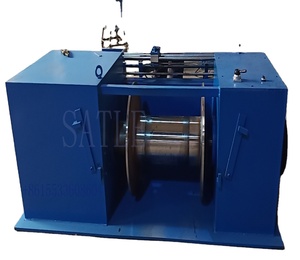

Materials and Construction

The construction of coil winding equipment involves durable materials that can withstand the rigors of industrial environments. The design considerations ensure that these machines can operate consistently under the demands of heavy usage, which is critical for maintaining production efficiency and equipment longevity.

Advantages of Modern Winding Machines

Modern coil winding rewinding machines offer significant advantages in terms of production efficiency and quality. Their automated processes reduce the potential for human error, ensuring that each coil meets the necessary specifications. The precision of these machines also allows for the production of coils that are essential for the increasingly sophisticated electronic components used in today's technology.

Choosing the Right Machine

Selecting the appropriate coil winder requires an understanding of the specific needs of your operation. Factors such as production volume, coil size, and the type of coils needed are crucial in determining the most suitable machine. Alibaba.com serves as a platform to explore a wide array of options, connecting businesses with a diverse selection of manufacturers to find the right fit for their requirements.