Popular in your industry

Related Searches:

Top categories

About custom moulding foam

Introduction to Custom Moulding Foam

Custom moulding foam stands as a versatile material used in various industries, offering flexibility in application and durability. This category encompasses a range of foam solutions tailored to meet specific requirements, making it an essential component in numerous manufacturing and design processes.

Types and Applications

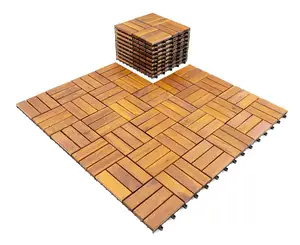

The diversity of custom foam moulding allows for its use in multiple sectors. From intricate millwork to robust industrial components, these foams adapt to the needs of each project. In the realm of art, custom moulding foam provides artists with a malleable medium to express creativity without compromising on longevity.

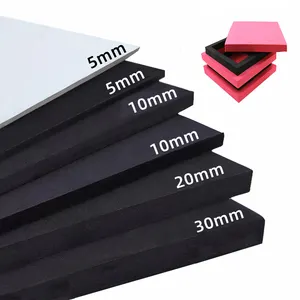

Material Composition and Features

Custom moulding foam is crafted from various materials, including polyurethane, polystyrene, and polyethylene. Each type offers unique characteristics, such as shock absorption, thermal insulation, and acoustic properties. The selection of material directly correlates with the intended use, ensuring optimal performance.

Advantages of Custom Foam Moulding

The advantages of using custom moulding foam are manifold. Its resilience under pressure and ability to withstand different conditions make it a reliable choice for long-term applications. Furthermore, the availability of custom foam moulding in diverse shapes and forms enhances its suitability for complex designs and applications.

Assurance of Resilience

Products within the custom moulding foam category are subjected to rigorous testing to ensure they meet the demands of their applications. This testing is designed to provide an assurance of the foam's durability and performance under various conditions.

Aesthetic and Functional Versatility

Beyond functionality, custom foam moulding also offers aesthetic versatility. Some options come with pre-marked designs, adding an extra layer of visual appeal to the final product. This dual capability makes custom moulding foam a preferred choice for both practical and decorative purposes.