Exploring Surface Grinding Machines for Cylinder Heads

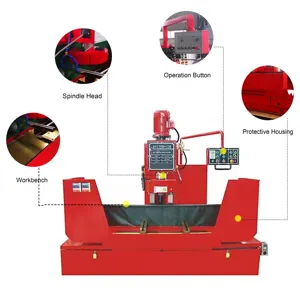

Surface Grinding Machines for Cylinder Heads are engineered to streamline the labor-intensive task of grinding engine parts, especially cylinder heads. By employing a grinding wheel, these machines meticulously remove material to produce a level surface, which is crucial for superior engine function. They are indispensable tools in workshops, automotive repair centers, and any sector that demands precise cylinder head grinding.

These machines operate on the principle of subtracting material from the cylinder head's upper layer. An abrasive-coated grinding wheel is affixed to a spindle inside the apparatus. Upon activation, the spindle and wheel rotate, with the wheel's coarse surface methodically wearing down the metal until the cylinder head achieves the requisite smoothness and evenness. This not only readies the cylinder head for additional machining but also ensures it forms an effective seal within the engine's combustion chambers.

Variants of Surface Grinding Machines for Cylinder Heads range from single to multiple spindle versions. They may be manually controlled or operated via computer numerical control (CNC), with the latter providing enhanced precision and automation. The decision between manual and CNC depends on the workload, the intricacy of the cylinder head design, and the desired quality of finish.

Diverse Types of Surface Grinding Machines for Cylinder Heads

The secondary market for machinery offers a plethora of surface grinding machines, each suited to particular needs and precision levels. Examples include:

-

Horizontal Spindle Surface Grinding Machine (HSSM): The most prevalent type, this grinder secures the workpiece on a magnetic chuck or similar holding device. With a horizontally rotating spindle, it is adept at grinding flat surfaces and edges.

-

Vertical Spindle Surface Grinding Machine (VSSM): Featuring a vertical spindle, this less common variant is versatile, capable of grinding metal block end faces or sharpening tools.

-

Universal Surface Grinding Machine: Designed for a wide range of materials and complex shapes, these machines boast dual vertical spindles, enabling simultaneous grinding on both sides of an object, which is efficient for mass production.

-

CNC Surface Grinding Machine: Equipped with computer numerical control, these machines offer precise, automated grinding. They can be programmed for intricate grinding patterns and tool changes without manual input.

Selecting the Right Surface Grinding Machine for Cylinder Heads

Choosing the appropriate Surface Grinding Machine for your enterprise requires a clear understanding of your cylinder heads' specifications and your projected workload. Consider the following:

-

Material Compatibility: Verify that the machine is capable of handling the material of your cylinder heads, whether it's iron, steel, or aluminum.

-

Workpiece Size: Ascertain the maximum dimensions of cylinder heads the machine can manage. It should be sufficiently large to process your components without sacrificing quality.

-

Accuracy and Precision: Opt for machines renowned for their precision. Components that are machined to close tolerances necessitate a machine of comparable accuracy.

-

Volume Capability: Assess your volume needs. Automated systems may be required for large-scale production, capable of handling numerous heads and intricate shapes with minimal setup.

-

Ease of Use: For manual or semi-automatic machines, ensure they are user-friendly and can be operated effectively by your workforce.

Discovering Surface Grinding Machines for Cylinder Heads on Alibaba.com

Alibaba.com emerges as a leading online marketplace for those in search of dependable and efficient surface grinding solutions for cylinder heads. The platform showcases a vast array of grinders for diverse industrial uses—ideal for manufacturing facilities, repair shops, construction firms, or any other industry in need of precise finishing tools.

With a global network, Alibaba.com connects purchasers with suppliers worldwide, offering a broad selection of surface grinding machines that satisfy various technical and commercial criteria. The platform's intuitive interface enables users to refine searches by key attributes such as high productivity or versatility, ensuring the discovery of a machine that meets specific demands.

Alibaba.com's dedication to secure trading, exemplified by services like Trade Assurance, provides businesses with confidence when investing in substantial equipment. With customization options to suit unique needs and support services including local language assistance and a mobile-friendly experience, Alibaba.com transcends the role of a marketplace to become a partner in international commerce, committed to aiding businesses in their operational success.

Frequently Asked Questions about Surface Grinding Machines for Cylinder Heads

What is the purpose of a surface grinding machine?

A surface grinding machine is chiefly employed to achieve a smooth, flat finish on workpieces by guiding a grinding wheel across the surface.

How does a surface grinding machine function?

A surface grinding machine employs a spinning abrasive wheel to precisely grind and finish workpieces, yielding a smooth and level surface.

Which materials can be processed by a surface grinding machine?

Surface grinding machines are capable of processing an array of materials, including metals, plastics, and composites, as well as achieving various surface finishes.

What are the different types of surface grinding machines available?

There are multiple types of surface grinding machines, such as horizontal spindle surface grinders, vertical spindle surface grinders, and double-disc surface grinders, each designed for specific tasks and applications.

What factors should be considered when selecting a surface grinding machine?

In choosing a surface grinding machine, one should consider the workpiece material hardness, the abrasive type required for the task, the desired surface finish, and the machine's precision and capacity.

How can I ascertain that a surface grinding machine meets my business's needs?

Determine your business's specific requirements, such as surface finishing, precision, or volume production, and select a machine that aligns with these needs.

What does 'precision' signify in the context of surface grinding?

In surface grinding, 'precision' refers to the machine's capability to deliver a high-quality finish with extremely tight tolerances, often within 0.0001 millimeter.

Is it possible to use a surface grinding machine for other grinding tasks?

Although surface grinding machines are highly versatile, they are best suited for tasks that demand a consistent and fine finish, particularly on metal surfaces.

What safety measures should be taken when operating a surface grinding machine?

Operators should don personal protective gear such as safety glasses, gloves, and hearing protection. Moreover, the machine should be used safely and the work area kept free from obstructions.

How should a surface grinding machine be maintained?

Routine maintenance for a surface grinding machine includes inspecting and replacing abrasive wheels, cleaning the machine bed and guards, and ensuring proper lubrication of moving components.

Why is wheel grit important in surface grinding?

The grit of the wheel determines the roughness or fineness of the surface finish. Lower grit numbers are appropriate for coarse work, while higher numbers are suited for fine finishing tasks.

Can a surface grinding machine be used to sharpen knives?

Although primarily designed for creating flat surfaces, surface grinding machines can also sharpen knives if equipped with the correct abrasive wheel.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4