Popular in your industry

Top categories

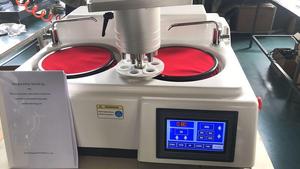

About cylindrical polisher

Introduction to Cylindrical Polishers

Cylindrical polishers are essential tools in metalworking and finishing industries, designed to refine the surface of cylindrical objects. These robust machines are engineered to smooth and enhance the texture of various metals, ensuring a polished finish for both aesthetic and functional purposes.

Types and Applications

The versatility of cylindrical polishers is evident in their applications across different sectors. In the automotive industry, they are instrumental in achieving the smooth finish on metal parts, while in the medical field, they are used to polish surgical instruments. The aviation sector also relies on these polishers for the maintenance of aircraft components. For laboratory research, metallographic polishers are utilized to prepare samples for microscopic examination, revealing the internal structure of metals.

Features and Technologies

Cylindrical polishing machines come equipped with various features tailored to the size and shape of the metal. Large-scale operations use heavy-duty polishers with multiple wheel heads that can be adjusted to accommodate different pipe sizes. These machines facilitate a continuous polishing process, enhancing efficiency. For smaller, intricately shaped metals, vibratory polishers are employed, which use a combination of vibration and polishing mediums to achieve a uniform finish.

Machine Specifications

The specifications of cylindrical polishing equipment vary widely. Large machines designed for long steel pipes can reach weights of several tons and are powered by motors with significant kilowatt ratings. These machines can polish at speeds ranging from 20 meters per minute to over 30 meters per minute. Conversely, vibratory polishers, suitable for smaller parts, have capacities from a few liters to over a thousand, with rotational speeds adjustable from 50 RPM to a rapid 1000 RPM.

Materials and Mediums

The construction of cylindrical polishers often involves durable materials capable of withstanding the rigors of metal polishing. The choice of polishing medium—ranging from specialized compounds to various grits—plays a crucial role in determining the finish quality on metals like steel and non-ferrous materials.

Advantages of Using Cylindrical Polishers

Utilizing cylindrical polishing tools offers numerous advantages, including the ability to efficiently remove imperfections such as rust, scratches, and oxide layers. The adaptability of these machines to different metal types and shapes makes them invaluable for achieving a high-quality finish in various industrial applications.