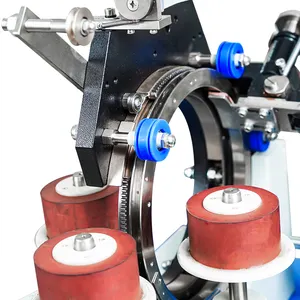

Introduction to Double Shaft Winding Machines

The realm of motor repairs and electrical appliance manufacturing is revolutionized by the advent of double shaft winding machines. These machines are pivotal in the process of coil rewinding, transforming the efficiency and output of workshops and factories. The double shaft design is specifically engineered to cater to the needs of businesses that require high-volume production of solenoids, transformers, and other coiled components.

Types and Applications

Within the industrial landscape, coil winding machines come in various forms, including autonomous, semi-automatic, and manual models. The double shaft variant stands out for its application in creating precise and uniform windings for electrical fans, transformers, and other electrical components. Its versatility extends to different commercial and industrial settings, as well as smaller operations such as home-based businesses.

Operational Features

A motor winding machine of this caliber typically requires minimal human intervention, with some models boasting full automation for enhanced precision. The operational ease of these machines allows for a single operator to manage the winding process, which significantly cuts down on labor costs and time. The precision of a double shaft motor winding machine ensures that each coil is wound to exact specifications, which is crucial for the functionality of electrical appliances.

Material and Construction Advantages

The construction of a double shaft winding machine involves robust materials that contribute to its longevity and consistent performance. The durability of these machines means they are a long-term investment for businesses looking to streamline their production processes. Furthermore, the machines are designed to operate with minimal maintenance, ensuring that production lines keep running without significant downtime.

Quality and Standards Compliance

Adherence to international production standards is a cornerstone of the automatic winding machine category. Suppliers on Alibaba.com ensure that each machine has undergone rigorous qualitative testing to meet these standards. This commitment to quality ensures that businesses receive a product capable of meeting their production needs without the concern of frequent maintenance or operational issues.

Maximizing Business Efficiency

Incorporating a double shaft winding machine into your business operations can significantly reduce production costs and increase output. The efficiency of these machines allows for more time to be allocated to other critical production tasks. With detailed instructions and the possibility of supplier-arranged demonstrations, businesses can quickly integrate these machines into their workflow, ensuring a smooth transition to more efficient production methods.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4