Understanding the Extrusion Screw

The extrusion screw is a pivotal component in the plastic extrusion process, serving as the heart of the extruder machine. It is designed to melt, mix, and push plastic materials through a die to shape them into continuous profiles. The efficiency and quality of plastic extrusion heavily rely on the precision and design of the screw.

Types of Extrusion Screws

There are primarily two types of extrusion screws used in the industry: the single screw extruder and the double screw extruder. The single screw variant is widely utilized for its simplicity and ease of operation, making it suitable for a broad range of materials. On the other hand, the double screw extruder, which includes the co rotating twin screw extruder, offers enhanced mixing, greater control, and higher output rates, ideal for more complex materials and applications.

Applications and Features

Extrusion screws are integral to producing a variety of plastic products, from pipes and sheets to films and profiles. The twin screw extruder is particularly effective for compounds that require thorough mixing or additives incorporation. Features such as screw design, length-to-diameter ratio, and flight geometry are tailored to meet the specific needs of the material being processed, ensuring optimal performance.

Materials and Advantages

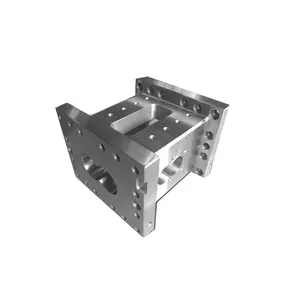

Constructed from durable materials, the extruder screw and barrel are engineered to withstand the pressures and temperatures of continuous operation. The choice of materials for the extrusion screw barrel is crucial to maintain tight tolerances and resist wear and corrosion, thereby extending the lifespan of the equipment.

Considerations for Selection

Selecting the right extrusion screw involves several considerations. The nature of the plastic material, desired output, and end-product specifications dictate the type of screw required. Factors such as damage resistance and the ability to maintain tight tolerances without compromising the integrity of the screw are paramount. Customization options for the screw barrel extruder setup can cater to specific operational requirements, enhancing the overall efficiency of the extrusion process.

Conclusion

In conclusion, the extrusion screw plays a critical role in the plastic extrusion industry. Whether it's a single screw extruder for straightforward tasks or a double screw extruder for more complex operations, the selection of the right screw type is essential for high-performance extrusion. With a variety of extrusion screw types available, the right choice can lead to significant advantages in the production process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4