Introduction to Fiberglass Rebar Price

Fiberglass rebar offers a revolutionary solution for construction projects, providing strength and durability without the weight of traditional steel reinforcing bars. As an innovative alternative, fiberglass rebar is increasingly sought after, prompting inquiries about fiberglass rebar price. Understanding the factors that influence these prices is crucial for contractors and purchasing managers looking to optimize their project budgets while ensuring quality and performance.

Types and Applications of Fiberglass Rebar

When discussing fiberglass rebar price, it is essential to note the various types of fiberglass rebar available, each tailored for specific applications:

- Standard Fiberglass Rebar: Commonly used in various construction projects, including residential and commercial buildings.

- Pultruded Fiberglass Rebar: Engineered for high-performance applications, ideal for structures exposed to harsh environments, such as bridges and marine installations.

- Gradually Increased Fiber Rebar: Designed for heavy-duty applications, offering superior tensile strength and resistance to corrosion.

- Composite Rebar: Combines fiberglass and other materials for enhanced properties, used in specialized industrial applications.

Applications are diverse, ranging from concrete reinforcement in infrastructures like highways and dams to residential foundations, making it vital to assess their suitability in any given project. The fiberglass rebar price generally reflects the material quality and type selected.

Features and Benefits of Fiberglass Rebar

Understanding the features of fiberglass rebar provides insight into its advantages, which can justify its price tag:

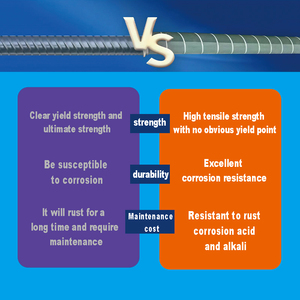

- Corrosion Resistance: Unlike steel, fiberglass rebar does not rust, making it ideal for construction in harsh environments or areas with high moisture levels.

- Lightweight: Significantly lighter than traditional steel rebar, leading to easier handling and lower shipping costs.

- High Strength-to-Weight Ratio: Provides comparable strength to steel, allowing for efficient load-bearing properties.

- Electromagnetic Neutrality: Suitable for applications where electromagnetic interference must be avoided, such as in tunnels or data centers.

- Reduced Labor Costs: Lightweight nature leads to faster installation, significantly cutting down on labor expenses.

These features contribute significantly to why fiberglass rebar price has become increasingly attractive for modern construction projects.

How to Choose the Right Fiberglass Rebar for Your Project

When evaluating your options in terms of fiberglass rebar price, consider the following factors to make an informed choice:

- Understand Your Project Requirements: Assess load specifications, environmental conditions, and exposure risks to decide on the appropriate type and grade of fiberglass rebar.

- Evaluate Cost vs. Durability: Higher prices might equate to superior quality and longevity; consider the total cost of ownership over the life of the structure.

- Supplier Reputation: Research suppliers with a solid track record; quality assurance and certifications often justify higher prices.

- Consider Local Availability: A locally-sourced product might save on transportation costs, affecting the overall pricing.

- Consult with Experts: Engaging with architects or structural engineers can provide insights into the best fiberglass rebar type for your specific needs.

Choosing the right fiberglass rebar can significantly impact both structural integrity and budget, making it essential to approach the decision wisely.