Introduction to Flat Wire Shaping Machines

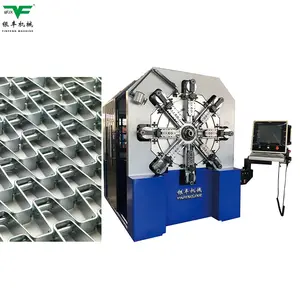

Flat wire shaping machines are specialized pieces of equipment designed for the transformation of metal wire into flat shapes. These machines are integral to various industries, serving as a cornerstone in the production of flat wire products. The versatility of these machines allows them to be utilized in numerous settings, including manufacturing plants and construction material shops.

Types and Applications

The flat wire shaping machine category encompasses a range of machinery, each tailored to specific metalworking tasks. These include units for metal & metallurgy machinery, cable manufacturing equipment, and bending machines. Their applications are diverse, catering to the production of components in sectors such as automotive, electronics, and construction, where precision-shaped flat wires are essential.

Features and Technical Specifications

Each flat wire shaping machine comes with a set of features that enhance its performance and usability. Common attributes include compatibility with various metals, adjustable shaping parameters, and the inclusion of modern control systems like PLCs. The technical specifications vary, with some machines offering additional functionalities to accommodate complex shaping processes.

Materials and Design

The construction of flat wire shaping machines involves robust materials that ensure durability and longevity. The design of these machines focuses on user safety, efficiency, and precision, with some models featuring advanced ergonomics for ease of use. The choice of materials also plays a crucial role in the machine's ability to withstand the rigors of continuous operation.

Advantages of Using Flat Wire Shaping Machines

Utilizing a flat wire shaping machine brings several advantages to the production process. These machines offer enhanced precision in shaping, which is critical for the functionality of the end product. They also contribute to increased production speed and consistency, which are vital for meeting the demands of large-scale manufacturing.

Choosing the Right Machine

Selecting the appropriate flat wire shaping machine requires consideration of several factors, including the specific application, desired output, and material compatibility. Prospective buyers can find a variety of options available to suit different operational needs, from simpler manual machines to fully automated systems.

Flat wire shaping machine

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4