Popular in your industry

Top categories

About machine shell maker

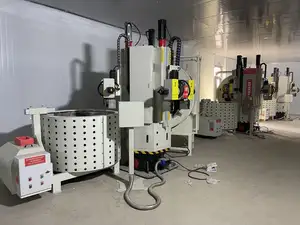

Introduction to Machine Shell Maker

A machine shell maker is a crucial piece of equipment used in various industries to manufacture different types of shells. These machines are designed to create precise and uniform shells for products such as tartlets, pasta, and other food items. The machine shell maker plays a significant role in streamlining the production process and ensuring consistent quality in the final products.

Technical Specifications

When considering a machine shell maker, important technical specifications to look out for include the production capacity, shell size variability, material compatibility, and automation features. The production capacity of the machine determines the output per hour, ranging from hundreds to thousands of shells. Additionally, the ability to produce shells of various sizes and shapes is essential for versatility in product offerings. Material compatibility refers to the types of ingredients the machine can work with, such as dough or batter. Automation features like programmable settings and self-cleaning mechanisms enhance efficiency and ease of use.

Types of Shell Makers

There are different types of machine shell makers available in the market, each catering to specific production needs. Some machines are specialized for producing tartlet shells, while others are designed for pasta shells. The Philips pasta maker shells offer unique features tailored for pasta production, such as extrusion capabilities and customizable settings. A shell pasta extruder is another type of machine shell maker that focuses on creating pasta shells with precision and consistency.

Features and Advantages

The features of a machine shell maker contribute to its overall performance and usability. Advanced features like adjustable shell thickness, speed control, and interchangeable molds enhance the versatility of the machine. The advantages of using a machine shell maker include increased production efficiency, consistent shell quality, and customization options for unique shell designs. These machines are essential for businesses looking to scale up their shell production while maintaining high standards.

Choosing the Right Machine Shell Maker

When selecting a machine shell maker for your business, consider factors such as production volume, shell size requirements, material compatibility, and budget constraints. Evaluate the machine's capacity to meet your production demands and the flexibility to produce different types of shells. It is also essential to choose a machine with durable construction and easy maintenance to ensure long-term reliability. Comparing different models and assessing their features will help you make an informed decision.

Maintenance and Care

Proper maintenance of your machine shell maker is essential to ensure smooth operation and prolong its lifespan. Regular cleaning and sanitation procedures should be followed to prevent contamination and maintain food safety standards. Lubrication of moving parts, inspection of electrical components, and timely replacement of worn-out parts are crucial for optimal performance. Following the manufacturer's guidelines for maintenance schedules and procedures will help keep your machine in top condition.

Overall, investing in a high-quality machine shell maker can significantly impact your production efficiency and product quality. By understanding the technical specifications, types, features, and maintenance requirements of these machines, you can make informed decisions to enhance your shell production processes.