Mylar PCB: An Overview

Mylar PCBs, a specialized category within the printed circuit board (PCB) market, are known for their unique construction, utilizing Mylar—a type of polyester film—as an insulating material. These PCBs are integral to various electronic applications due to their flexibility and durability. The Mylar film in these boards provides excellent insulation and has a significant impact on the performance of the final product.

Types and Applications

The versatility of mylar pcb designs allows for their use in a multitude of electronic devices. From simple electronic device circuits to more complex communication systems, the adaptability of pcb mylar sheets makes them suitable for a broad range of applications. This adaptability is due to the various types of Mylar PCBs available, each tailored to specific use cases and operational environments.

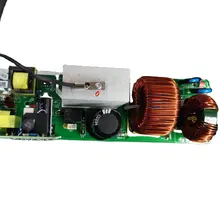

Features and Materials

Mylar PCBs are characterized by their material composition and the features that this composition provides. The Mylar film used in these PCBs is known for its thermal stability, chemical resistance, and dielectric strength. These features make mylar pcb options a reliable choice for applications requiring consistent performance under stress. Additionally, the material's flexibility allows for the creation of PCBs that can bend or flex during use, which is particularly beneficial for modern, compact electronic designs.

Advantages of Mylar PCBs

The advantages of using pcb mylar in circuit board design are numerous. Mylar PCBs offer enhanced durability and longevity, which is crucial for devices that undergo frequent use or are subject to harsh conditions. The insulation properties of Mylar also contribute to the overall safety and efficiency of the electronic components, reducing the risk of short circuits and other electrical issues.

Considerations for Selection

When selecting a mylar pcb, it is important to consider the specific requirements of the application. Factors such as the operating temperature range, flexibility needs, and the electrical properties required for the circuit should guide the selection process. It is also essential to evaluate the compatibility of the Mylar PCB with other components in the device to ensure optimal functionality.

Environmental and Manufacturing Standards

Mylar PCBs are produced in accordance with various environmental and manufacturing standards to ensure they meet the necessary quality and safety benchmarks. While selecting a pcb mylar product, it is advisable to consider the compliance of the product with these standards, which can provide an indication of the PCB's reliability and performance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4