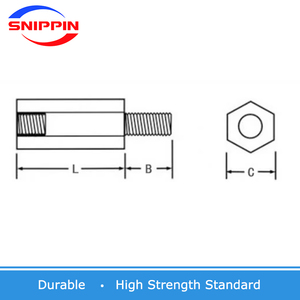

Nylon Spacer PCB: Introduction

Nylon spacer PCBs (Printed Circuit Boards) are essential components in electronic assemblies, providing reliable insulation and support for various electronic parts. These spacers are designed to separate components and maintain precise space and alignment within circuit assemblies. Made from durable and lightweight nylon, these spacers are resistant to chemicals and temperatures, making them ideal for diverse applications in industries such as aerospace, automotive, telecommunications, and consumer electronics.

Nylon Spacer PCB: Types

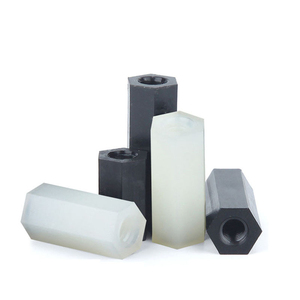

Nylon spacers for PCBs come in various types, each catering to specific needs and preferences. Understanding the types available can help you make an informed decision when selecting the right spacer for your application.

- Standard Nylon Spacers: Commonly used in most applications, featuring various lengths and diameters.

- Non-Conductive Spacers: Designed to provide electrical isolation between components, reducing the risk of short circuits.

- Heavy-Duty Nylon Spacers: Built for rugged environments, offering improved strength and durability.

- Custom Nylon Spacers: Tailored to meet specific dimensions or performance criteria for unique applications.

Nylon Spacer PCB: Applications

Nylon spacers play a pivotal role in numerous applications, ensuring that PCBs function effectively without compromising structural integrity. Here are some key applications where nylon spacers are indispensable:

- Electronics Assemblies: Widely used in assembling circuit boards, providing support and protection.

- Telecommunications: Help in insulating sensitive components in communication devices, maintaining signal integrity.

- Industrial Machinery: In heavy machinery and factory automation systems, they facilitate proper assembly and maintenance.

- Aerospace Components: Used in aircraft systems to ensure durability and lightweight characteristics.

Nylon Spacer PCB: Advantages

Choosing nylon spacers for your PCB applications comes with an array of advantages that can enhance the performance and reliability of your electronic assemblies. Some of the key benefits include:

- Lightweight: Nylon spacers are significantly lighter than metal alternatives, reducing the overall weight of the assembly.

- Corrosion Resistance: Chemical resistance prevents degradation from exposure to harsh working environments.

- Electrical Insulation: Serving as effective insulators, nylon spacers prevent electrical short circuits.

- Easy Installation: Their design allows for quick and straightforward installation, saving time during assembly processes.

- Cost-Effective: Nylon spacers are economically viable, offering great performance without breaking the bank.