Popular in your industry

Top categories

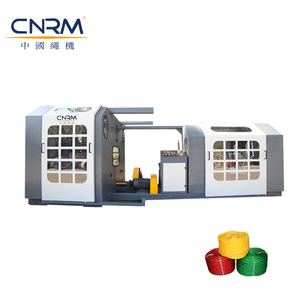

About pet broom monofilament drawing machine

Introduction to Pet Broom Monofilament Drawing Machines

The realm of brush production is witnessing a revolution with the advent of pet broom monofilament drawing machines. These machines serve as a cornerstone in the manufacturing of broom bristles, offering a spectrum of models tailored to meet diverse production demands. The category encapsulates equipment designed to synthesize monofilaments from PET (Polyethylene Terephthalate), a type of polyester known for its resilience and flexibility.

Types and Specifications

Variety is paramount when selecting a monofilament extrusion line. The market offers an array of machines varying in size, output capacity, and technological sophistication. This ensures that whether for a small-scale operation or a large industrial venture, there is a machine to fit the specific production volume and space constraints of the facility.

Applications and Performance

Monofilament produced by these machines is not limited to broom bristles. It finds applications in various industries, including brushes for cleaning, painting, and even in the textile sector. The performance of a monofilament making machine is critical, as it directly impacts the efficiency of production lines. These machines are engineered to optimize production, ensuring a balance between speed and quality of the monofilaments.

Features and Materials

A plastic filament making machine is often celebrated for its user-friendly interface and low maintenance requirements. The construction of these machines involves robust materials that offer resistance to wear and tear, extending the machine's lifespan and ensuring consistent performance. The materials used for the monofilaments are chosen for their durability and adaptability to various cleaning environments.

Advantages of Utilizing Advanced Machinery

Incorporating a synthetic filament extrusion line into your production process can significantly enhance efficiency. These machines are designed to minimize manual labor and save time, which can lead to increased profitability. Furthermore, the energy-efficient nature of a plastic broom filament making machine not only reduces operational costs but also supports environmental sustainability through lower energy consumption and recyclable material use.

Environmental Impact and Sustainability

Sustainability is a crucial aspect of modern manufacturing. A pet broom filament machine aligns with this principle by utilizing materials that are recyclable, thereby contributing to a reduction in environmental pollution. Additionally, the energy-efficient design of these machines ensures that the carbon footprint of production is kept to a minimum.