Popular in your industry

Related Searches:

Top categories

About pvc vacuum machine

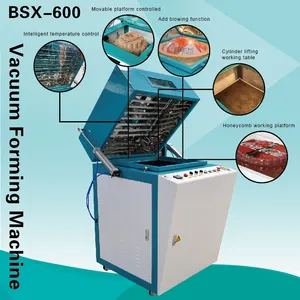

Introduction to PVC Vacuum Machines

The realm of woodworking and carpentry has evolved with the advent of modern machinery, and central to this progression is the PVC vacuum machine. This equipment is pivotal for shaping and bonding PVC material onto various substrates, often used in the production of cabinets, doors, and other furniture items. The technology behind these machines leverages vacuum pressure to adhere PVC onto MDF or similar materials, ensuring a seamless and durable finish.

Types of PVC Vacuum Machinery

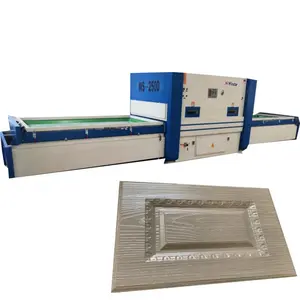

Diversity in woodworking demands versatility in equipment. The PVC vacuum press machine comes in various configurations to meet different production needs. From manual to automatic models, each machine offers unique features tailored for specific processes. The vacuum press machine PVC lineup includes single-table presses for small-scale operations and double-table presses for higher volume environments. Specialized PVC vacuum membrane press machines are designed to handle intricate shapes and sizes, providing a solution for complex designs.

Applications and Features

The application of PVC vacuum machines extends across multiple woodworking scenarios. These machines are not just limited to flat surface lamination but are also adept at covering complex contours and edges, making them indispensable in the production of 3D components. Features such as digital control systems, adjustable vacuum pressure, and temperature settings enable precision and control during the lamination process, ensuring consistent results across various production runs.

Materials and Advantages

A PVC vacuum membrane press machine is designed to work with a range of materials, including vinyl, PVC films, and wood veneers. The advantages of using such machinery are manifold. They provide an efficient method for applying a wide variety of finishes, enhance product durability, and offer an aesthetically pleasing look that is often required in the competitive furniture market. Additionally, the use of these machines can significantly reduce labor costs and increase production speed.

Maintenance and Safety

Maintaining a PVC vacuum press machine involves regular cleaning and adherence to maintenance schedules. Proper upkeep ensures the longevity of the machine and consistent performance. Safety is paramount when operating any woodworking machinery. It is essential that operators are trained to use the equipment safely, understanding all operational aspects to prevent accidents and ensure a safe working environment.

Choosing the Right Machine

Selecting the appropriate pvc vacuum machine is crucial for meeting production goals. Factors to consider include the size of the operation, the types of products being manufactured, and the desired output. Alibaba.com hosts a vast array of machinery options, allowing buyers to compare different models and features to find the right fit for their specific needs without the influence of brand bias.