Popular in your industry

Related Searches:

Top categories

About rspec brake pads

When it comes to ensuring the safety and performance of a vehicle, rspec brake pads are a critical component in the braking system. These pads are the result of advanced engineering and material science, designed to provide reliable stopping power under various driving conditions. The primary function of rspec brake pads is to create friction against the brake rotors, allowing drivers to decelerate smoothly and effectively.

Types and Characteristics of Rspec Brake Pads

The rspec brake pads come in various types, each tailored to different driving conditions and vehicle requirements. For instance, ceramic brake pads are known for their quiet operation and low dust production, making them ideal for daily driving in urban settings. On the other hand, carbon-fiber pads are suited for high-performance vehicles due to their high heat tolerance and aggressive stopping power. There are also specialized pads designed for heavy-duty applications, such as towing or off-road use, which feature enhanced strength and durability. By understanding the characteristics of each type, businesses can cater to a broad spectrum of customer needs, from the commuter seeking a smooth ride to the enthusiast demanding performance.

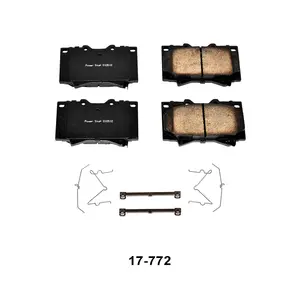

Structure and Design Features of Rspec Brake Pads

The structure of rspec brake pads is meticulously engineered. Each pad consists of a backing plate, which provides structural support, and a friction material that is responsible for the braking action. The bonding adhesive is a high-temperature-resistant compound that secures the friction material to the plate. Advanced features like thermal scorches, which are pre-burnishing on the pad surface, ensure a faster break-in period and more consistent performance. The inclusion of precision-cut pressure plates ensures even wear, which prolongs the lifespan of the pads and maintains braking efficiency.

Materials and Composition of Rspec Brake Pads

The composition of rspec brake pads is a sophisticated blend of materials including ceramics, organic compounds, and sometimes even metallic fibers. Ceramics are favored for their heat dissipation properties, which contribute to the pads' performance during high-temperature braking. Organic materials offer quieter operation and less rotor wear, making them suitable for everyday use. The choice of materials is a careful balance aimed at providing optimal performance, longevity, and noise control, which are critical factors for both safety and comfort.

Business Usages and Applications of Rspec Brake Pads

In the business realm, rspec brake pads find their applications in various industries. For delivery companies, consistent and reliable braking is non-negotiable, given the stop-and-go nature of urban driving. In the realm of public transportation, where safety and passenger comfort are paramount, the smooth operation of these brake pads is a key selling point. Additionally, in high-performance automotive sectors, such as racing or luxury car servicing, the superior heat resistance and stopping power of rspec pads are highly valued. These diverse applications illustrate the product's ability to create business value by meeting specific industry needs.

Functions of Rspec Brake Pads

The primary function of rspec brake pads is to convert the kinetic energy of the vehicle into thermal energy through friction, leading to deceleration. They are designed to work effectively under a range of conditions, from wet and icy roads to dry, hot climates. The pads must also function quietly and with minimal vibration, contributing to a more comfortable driving experience. Additionally, they are tasked with providing a consistent pedal feel, which gives drivers confidence in their vehicle's braking system.

Features of Rspec Brake Pads

The features of rspec brake pads set them apart from competitors. These include their optimized design for heat dissipation, which reduces the risk of brake fade during intense use. The use of advanced friction materials ensures a longer lifespan and less frequent need for replacement. Moreover, the low-dust formulation keeps wheels cleaner and maintains the aesthetic appeal of the vehicle. These unique selling points are crucial for businesses that prioritize long-term cost savings and customer satisfaction.

Benefits of Rspec Brake Pads

The benefits of rspec brake pads are numerous. They provide a safer driving experience by ensuring reliable stopping power. The reduced wear on brake rotors extends the overall life of the braking system, offering cost savings to vehicle owners. The comfort factor is also significant, as these pads operate quietly and with less vibration, enhancing the quality of the ride. For businesses, these benefits translate into a strong value proposition for their customers, whether they are individual car owners or operators of vehicle fleets.

How to Use and Maintain Rspec Brake Pads

Effective operation of rspec brake pads begins with proper installation, which should always be performed by a qualified technician. Once installed, regular maintenance checks are crucial. This includes monitoring pad thickness and looking for signs of uneven wear, which could indicate a problem with the brake caliper or the suspension system. Cleaning the pads and the surrounding components with appropriate tools and solutions can prevent buildup of debris, which can affect braking performance.

How to Choose and Install Rspec Brake Pads

Choosing the right rspec brake pads involves considering the vehicle's make and model, as well as the driver's typical use cases. For installation, the process must be in accordance with the manufacturer's specifications. This includes applying the correct torque to caliper bolts and using any necessary lubricants on the caliper slides to ensure smooth operation. Proper bedding-in of the pads after installation is also critical to ensure the best performance and longevity.

Target Audience and Needs for Rspec Brake Pads

The target audience for rspec brake pads is diverse, ranging from automotive enthusiasts seeking performance upgrades to fleet managers who need reliable components for their vehicles. The product meets the needs of this wide audience by offering a range of options tailored to different driving styles and conditions. For the performance-minded, pads with higher heat tolerance and aggressive grip are available, while those prioritizing comfort and longevity might opt for ceramic or organic options.

What are the signs that rspec brake pads need replacing?

Signs that rspec brake pads need replacing include a noticeable decrease in braking performance, unusual noises such as squealing or grinding when braking, and a longer stopping distance. Additionally, many brake pads have wear indicators that produce a high-pitched warning sound when the pad material has worn down to a critical level. Regular inspections can help identify these signs early, ensuring that the brake pads are replaced before they compromise the vehicle's safety.

How do rspec brake pads compare to other brands?

Rspec brake pads are often compared to other brands on the market in terms of performance, durability, and price. While some brands may offer lower prices, rspec pads are typically recognized for their superior quality and longer lifespan. They are also praised for their ability to provide comfortable braking, which is a testament to their design and material composition. For businesses, investing in rspec brake pads can mean fewer replacements and better performance for their fleet or customers' vehicles.

Why should businesses choose rspec brake pads for their fleets?

Businesses should choose rspec brake pads for their fleets because of their proven reliability and cost-effectiveness in the long run. The enhanced safety features, coupled with the reduced need for frequent replacements, make them an economically sound choice for any business that relies on transportation. Furthermore, the wide applicability across different vehicle models ensures that fleet managers can standardize their brake pad inventory, simplifying maintenance operations and inventory management.

For business buyers seeking dependable and efficient braking solutions, rspec brake pads on Alibaba.com offer a blend of quality, performance, and value. Their robust design, tailored to meet the demands of various vehicle models, makes them an essential component for maintaining vehicle safety and operational standards.