Introduction to Section Rolling Machines

Section rolling machines, integral to metalworking, are designed for bending and shaping metal sections into curves or complete circles. These robust machines cater to a variety of metals, ensuring precision and efficiency in production. Their automated operations minimize human error, leading to consistent output quality.

Types and Applications

Profile bending machines and angle rollers are common types of section rolling machines, each serving distinct functions. Profile benders manipulate metal into various forms, while angle rollers focus on creating precise angles. Applications span across construction, automotive, and manufacturing industries, where the creation of tubes, coils, and structural components is essential.

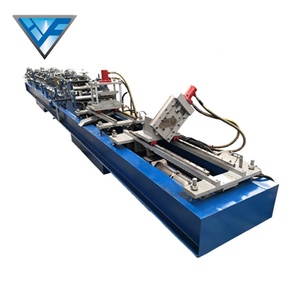

Operational Features

The operational features of a section rolling machine include user-friendly interfaces and programmable systems that facilitate ease of use without the need for extensive training. Their automated processes ensure that each metal section is rolled to exact specifications, enhancing production line efficiency.

Material Considerations

When selecting a metal rolling machine, it's crucial to consider the compatibility with various materials. Machines vary in capacity, with some designed for heavy-duty metals, while others are suited for lighter gauges. The material's thickness and strength are pivotal factors influencing the choice of machine.

Advantages of Modern Rolling Technology

Modern section benders offer significant advantages in terms of production speed and waste reduction. The precision of these machines ensures that material usage is optimized, leading to cost-effective operations. Additionally, the versatility of a hydraulic rolling machine allows for its application across multiple projects without the need for multiple machines.

Choosing the Right Machine

When in the market for a plate bending roll, it's important to assess the machine's construction. Machines crafted from robust materials like steel offer longevity and consistent performance. While Alibaba.com does not manufacture these machines, the platform provides a comprehensive selection from various suppliers to meet diverse operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4