Popular in your industry

Related Searches:

Top categories

About stapler plastic injection mould

Introduction to Stapler Plastic Injection Moulds

The realm of manufacturing is ever-evolving, and stapler plastic injection moulds stand as a testament to this progression. These moulds are pivotal in producing staplers, a staple in offices and schools worldwide. The process involves injecting molten plastic into a pre-designed mould to form various components of a stapler. This technique is favored for its precision and efficiency in mass production.

Types and Applications

There are multiple types of injection moulds for staplers, each tailored for specific parts and functionalities. From creating intricate internal mechanisms to the more visible parts like the casing, these moulds are versatile. Their applications are not limited to just office supplies; they extend to industrial and commercial settings where staplers are used in packaging and assembly lines.

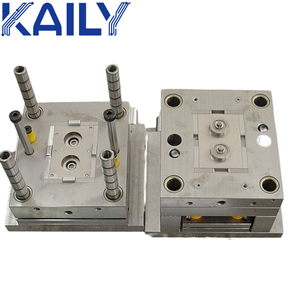

Features and Materials

The features of a stapler mould are as diverse as their applications. They range from simple two-part cavities to complex multi-cavity moulds for high volume production. The materials used in mould making are crucial for the durability and quality of the final product. Common materials include various grades of steel and aluminum, each selected based on the required lifespan and the intricacy of the stapler parts being moulded.

Advantages of Precision Moulding

Precision is paramount when it comes to stapler plastic injection moulding. The accuracy of these moulds ensures that each stapler component fits seamlessly, guaranteeing functionality. Moreover, the repeatability of the process ensures uniformity in mass production, which is essential for brand consistency and reliability.

Optimizing Production with Stapler Moulds

Optimization of production is a significant advantage when utilizing plastic injection moulds for staplers. By standardizing certain elements of the mould, such as lift bars and clamp slots, manufacturers can streamline the production process, making it more efficient and cost-effective. This standardization also simplifies the interchangeability of parts, reducing downtime and maintenance costs.

Choosing the Right Mould

Selecting the appropriate stapler plastic injection mould is crucial for any project. Factors to consider include the type of plastic material, the complexity of the design, and the expected production volume. Suppliers on Alibaba.com offer a range of options to cater to these needs, providing versatility without compromising on the precision required for effective stapler manufacturing.