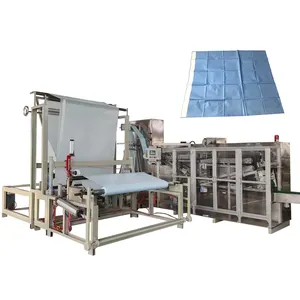

Surgical Tape Machine Overview

The surgical tape machine category encompasses a variety of equipment designed to produce adhesive surgical tapes used in medical settings. These machines are integral to the production of tapes that secure bandages, dressings, and medical devices to the skin. With a focus on efficiency and precision, surgical tape machines cater to a range of applications in the healthcare industry.

Types and Applications

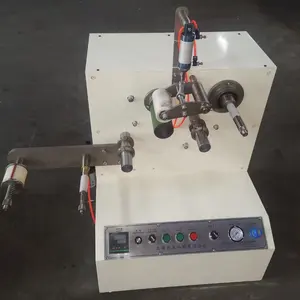

Surgical tape machines come in several types, including packaging machines, coating machines, and weaving machines, each serving a unique function in the production line. These machines are versatile, handling materials for apparel, food, and chemical industries, but are specifically optimized for medical-grade tape production. The application of these machines spans from small-scale operations to large manufacturing plants, reflecting the diverse needs of the medical supplies sector.

Technical Features

When selecting a surgical tape production machine, technical features such as high-accuracy, ease of operation, and competitive pricing are crucial. These machines are engineered to meet the stringent standards of the medical industry, ensuring that the surgical tapes produced are of consistent quality and reliability. Advanced features may include precision coating technology and automated weaving systems, which contribute to the overall efficiency of the production process.

Material Handling and Machine Advantages

The materials used in surgical tapes require careful handling to maintain their adhesive properties and sterility. Surgical adhesive tape machines are designed to manage these materials with care, preventing contamination and degradation. The advantages of using specialized machinery include improved production speed, consistent tape quality, and reduced material wastage, which are critical factors in the cost-effective production of surgical tapes.

Choosing the Right Machine

When it comes to selecting the right surgical tape manufacturing equipment, factors such as the machine's adaptability to different materials, production capacity, and footprint are important considerations. Prospective buyers should evaluate the machine's specifications to ensure it aligns with their production requirements and space constraints. Additionally, the ease of maintenance and availability of parts are practical aspects that can influence the decision-making process.

Conclusion

In conclusion, the surgical tape making machine is a specialized piece of equipment that plays a pivotal role in the healthcare industry. Its ability to produce high-quality surgical tapes efficiently makes it a valuable asset for medical product manufacturers. While selecting a machine, it is essential to consider the technical specifications, material compatibility, and operational advantages to ensure it meets the production goals and maintains industry standards.

![[JT-GW500-A6] Surgical Adhesive Tape Machine Adhesive Tape Winding Machine Bopp Adhesive Tape Printing Machine](https://s.alicdn.com/@sc04/kf/H0364a3fc7c254102bf7f47afe17b0c3bC.jpg_300x300.jpg)

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4